CASES

MISSON

Aiming to reduce wear of cutting edges and improve production efficiency

In the die-cutting of magnet sheets, the ferrite (iron oxide) contained in the sheet material causes severe wear on the cutting edge,

resulting in a decrease in production efficiency.

Is there a blade that can reduce wear of the cutting edge?

Blade material used : SID50 0.7x23.6 7080 ∠43° (center bevel)

Cutting target : Magnet sheet 1.0mm

SOLUTION

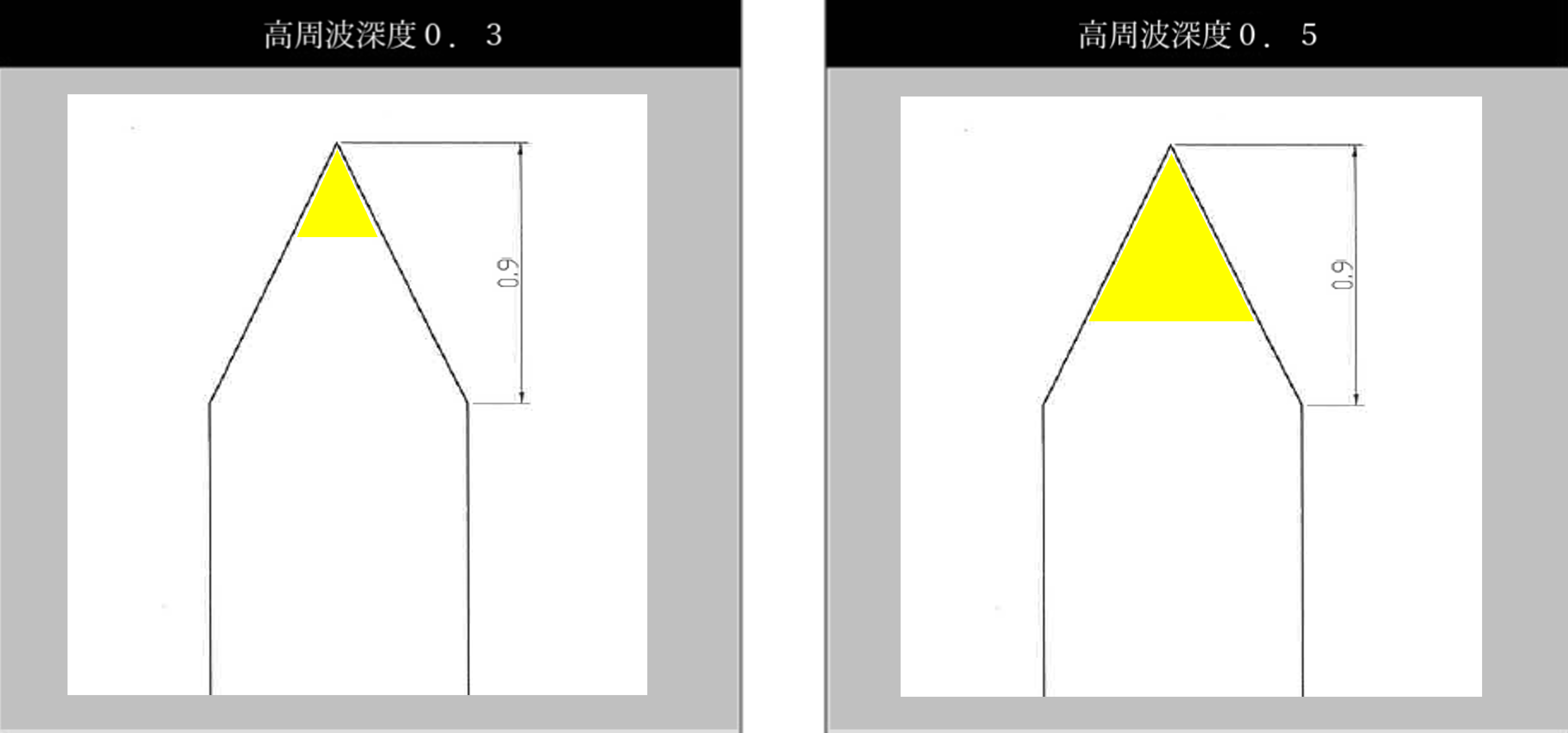

The normal cutting rule has a cutting edge high-frequency depth of “0.3”.

We propose the “SID50” with a blade edge high-frequency depth of "0.5".

By making the edge hardening layer deeper than usual, the blade edge wear resistance has been improved and production efficiency can be expected to increase.

High-frequency depth comparison image

The use of SID50 has reduced wear of the cutting edge,

leading to increased durability of the blade (improved production efficiency).

It is effective not only for die-cutting of magnet sheets, but also for die-cutting of materials where wear of the cutting edge is a concern.