BEAUTIFUL CUTLINE.

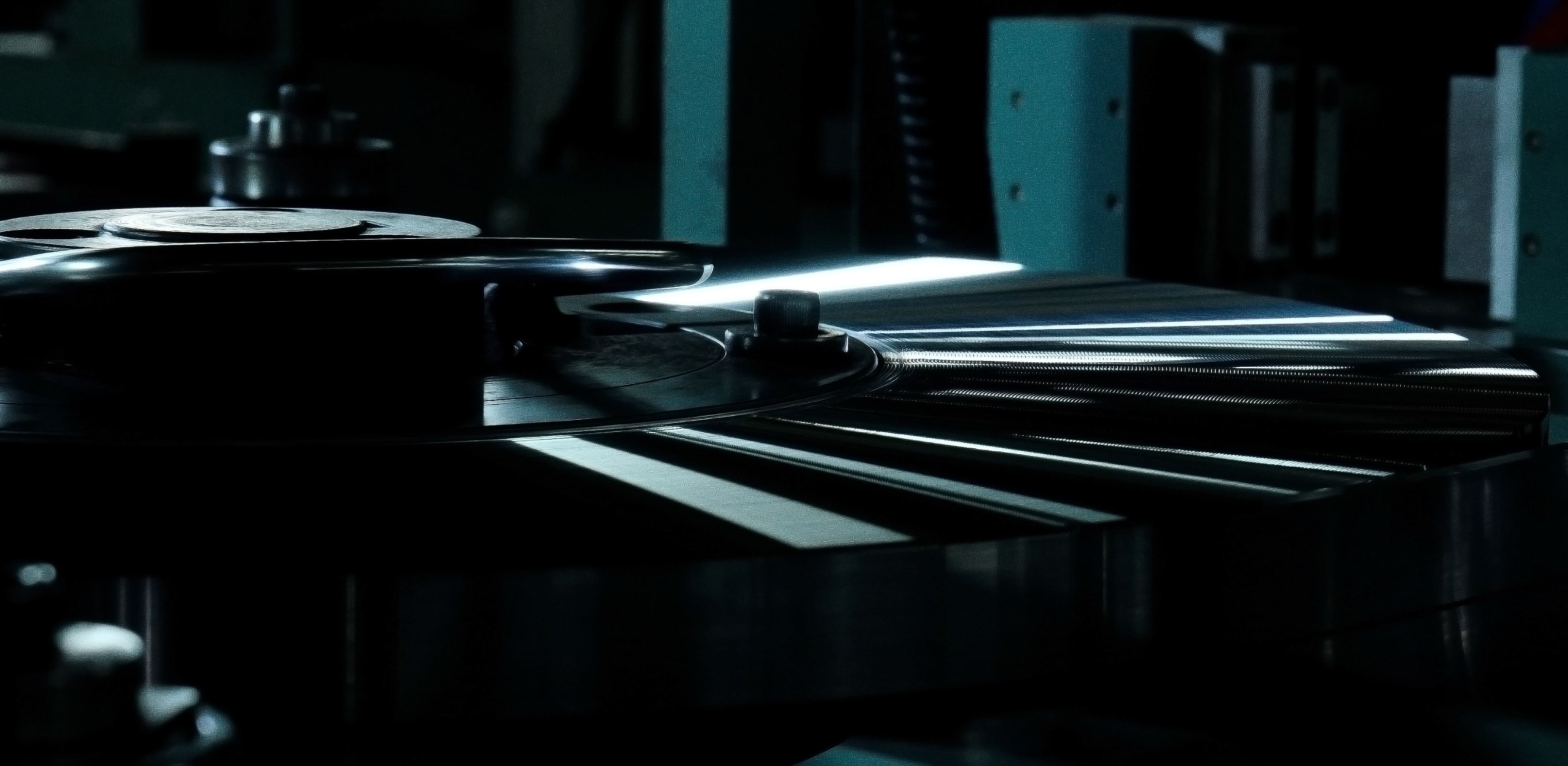

Nakayama MIR are ultimate CUTTING RULES, used to cut through all sorts of materials around the world, from films used in LCD TVs to high-added-value packaging.Over the course of approximately a century since our founding, Nakayama has engaged with CUTTING RULES, gotten to know them thoroughly, and has developed unique processing technology and know-how. It is in this context that MIR was created and continues to evolve.With unevenness of height kept to the utmost minimum and a mirror finish applied, the blade edge boasts the ultimate sharpness. These features achieve a keen and beautiful cutting surface that can be said to embody Nakayama’s history.

The key characteristics of Nakayama MIR are unparalleled sharpness and height precision, but it also features a high degree of bendability.

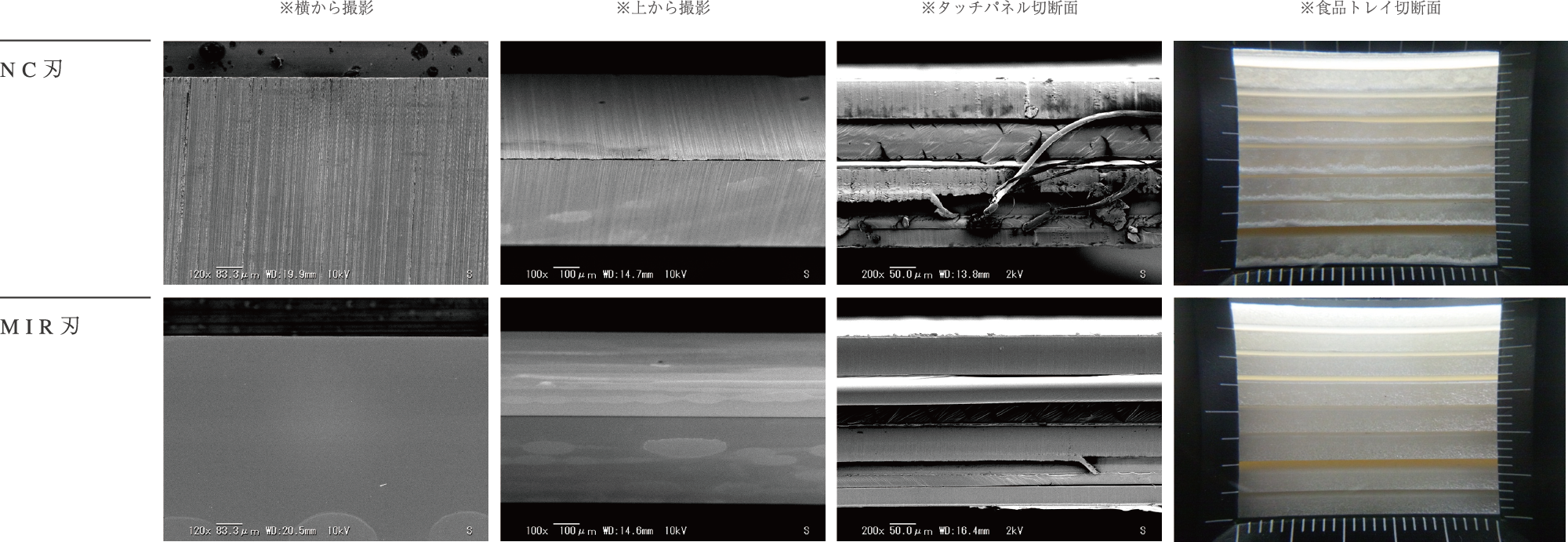

As the image shows, Nakayama MIR achieves a smoother polished surface than conventional products.

In addition to blade edge sharpness resulting from utmost minimization of height unevenness and a mirror finish, Nakayama MIR is easily processed and gains a reputation for being able to solve a wide range of problems.

To make better products, Nakayama designs and manufactures the equipment used to produce MIR blades in-house. This means we can steadily update and constantly improve our products.Also, we have selected the optimal grinding wheel for MIR blades based on trial and error over the course of our long history.

The MIR pre- and post-process stages are important as well. We focus on fundamentals such as heat treatment and pre-polishing during the pre-process stage, as well as during the post-process stage after MIR is complete, and succeeded in improving non-contact automation of cutting equipment that cuts to exact product sizes.

About 30 years ago, in 1992, we launched research and development to fulfill customer requests for “CUTTING RULES with blade edges that do not break even when bent.”Development was not easy, and a cycle of trial and error was repeated many times. The grinding wheel grain produced cracks in the blade edge. For this reason, we ground it many times with a fine grinding wheel to minimize the groove and make it as thin and shallow as possible.After this process, the blade finally emerged shining and the groove disappeared, resulting in a blade that can accommodate bending and boasts excellent sharpness. The product name “MIR” is derived from “mirror.”In addition to the blade polishing method, we also focus closely on the grinding wheel and produce grinding wheels only for MIR, which has led to the current high level of product quality and consistency.