CASES

MISSON

Improving the balance of flatbed die cutting machine

Reduce "make-ready" time and improve the life of the dieboard.

In balancing pressure on a flatbed die cutting machine,

a large amount of time is required for "make-ready" time,

resulting in a significant decrease in production efficiency.

By reducing the time required for make-ready time,

we would like to realize a more efficient production system.

SOLUTION

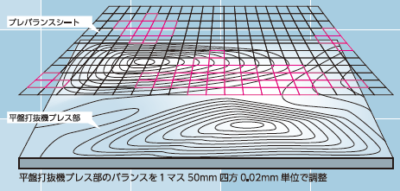

Prebalance 2.0 (PressBalance System 2.0) to significantly reduce make-ready time

Prebalance 2.0 (PressBalance System 2.0) is adopted in flatbed die cutting press section

to improve balance and reduce make-ready time.

Results of use

BEFORE

Since the work is done with test die-cutting, it takes about 3 to 4 hours for make-ready process.

AFTER

Prebalance system 2.0 (PressBalance System 2.0) has corrected the balance of the machine and significantly reduced make-ready time.

In this case,make-ready process could be done in less than one hour.

The use of the Prebalance 2.0 (PressBalance System 2.0) greatly reduced the make-ready time,

extended the life of the dieboard, and greatly improved production efficiency.