CASES

MISSON

Providing Steel Rules in Ultra-Small Lots with Ultra-Short Lead Time

For test die production, only a few meters of cutting rule material are actually needed.

However, in conventional steel rule manufacturing, the minimum production lot was 100 meters,

making it difficult to produce a wide variety of prototypes due to cost and inventory risks.

Goal : To manufacture test dies at low cost and with a quick turnaround.

SOLUTION

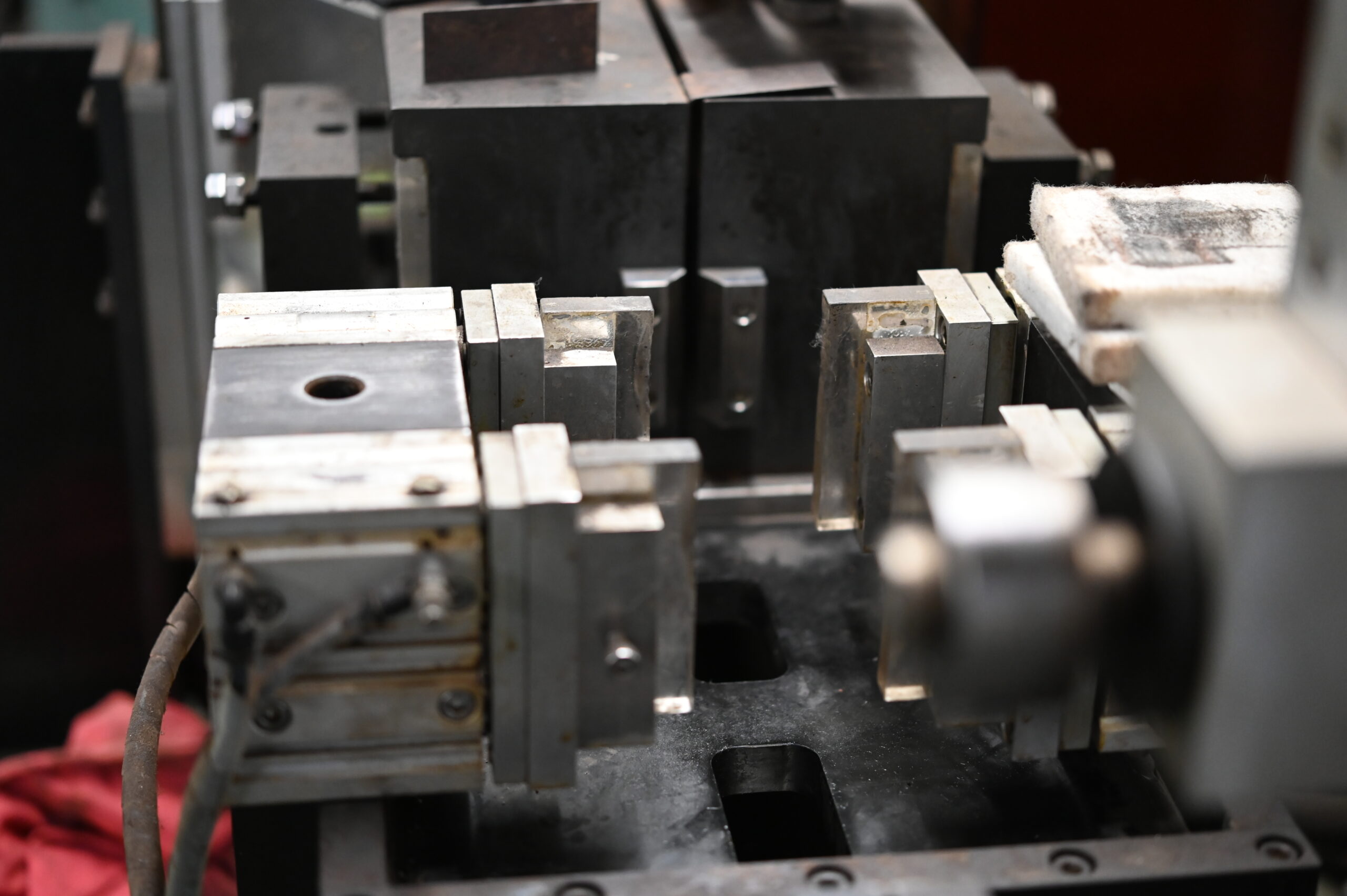

In-House Development of the “10M Line”

Nakayama developed a proprietary production line capable of manufacturing in ultra-small lots of around 10 meters —

separate from the conventional 100-meter minimum lot line.

This “10M Line” enables the supply of various types of steel rule materials

at low cost, short lead time, and without inventory risk.

Results of use

Leveraging Nakayama’s extensive experience and technical expertise,

we propose the most suitable steel rule materials based on the cutting material, shape, and required precision.