CASES

MISSON

Verification of Suitable Steel Rules Using a Die Cutting Performance Testing Machine

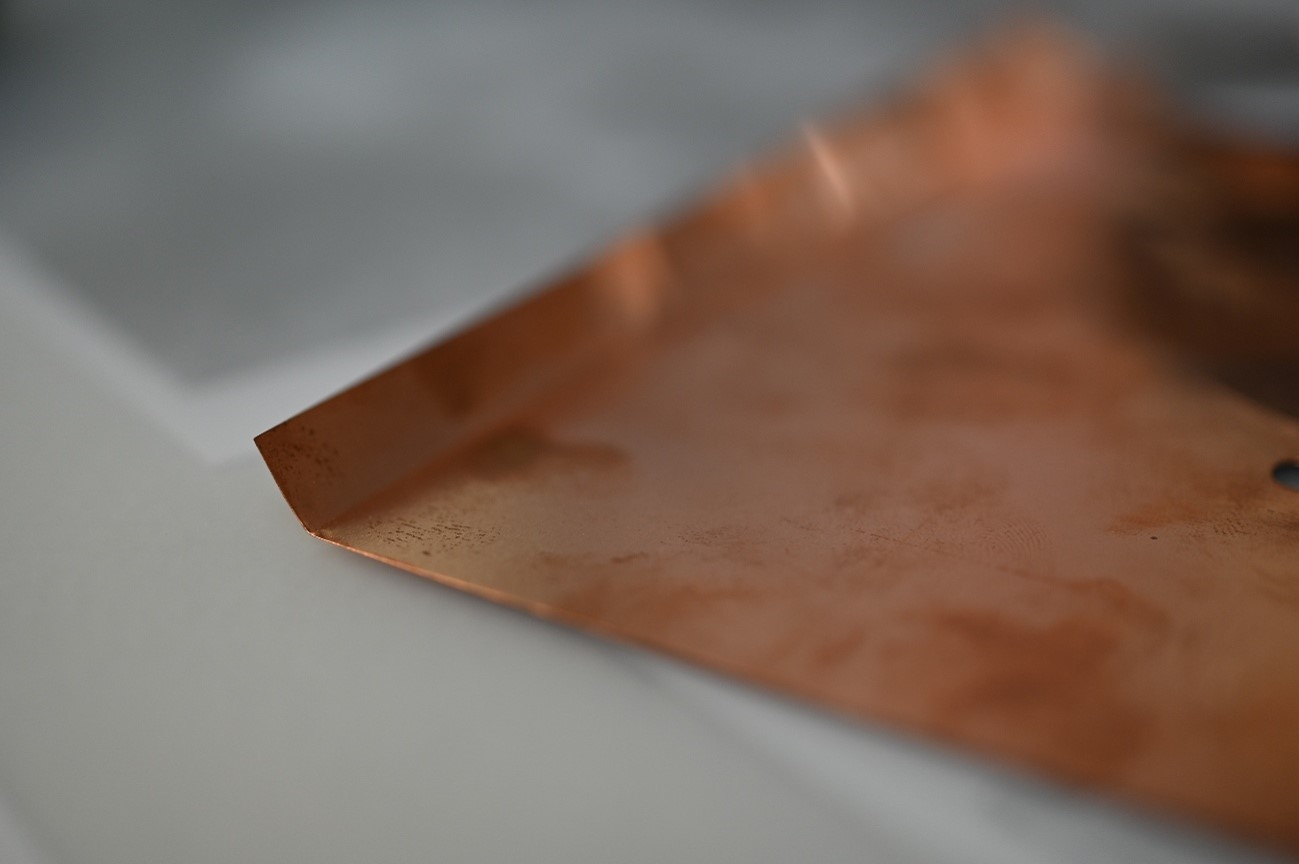

Cutting thin copper foil is an extremely delicate process.

Even a deviation of just a few millimeters can have a significant impact on the subsequent steps.

Until now, this work relied heavily on manual operation, but it was time-consuming and had reached its limit in terms of efficiency.

The challenge was clear. Is there a way to improve efficiency while maintaining quality?

SOLUTION

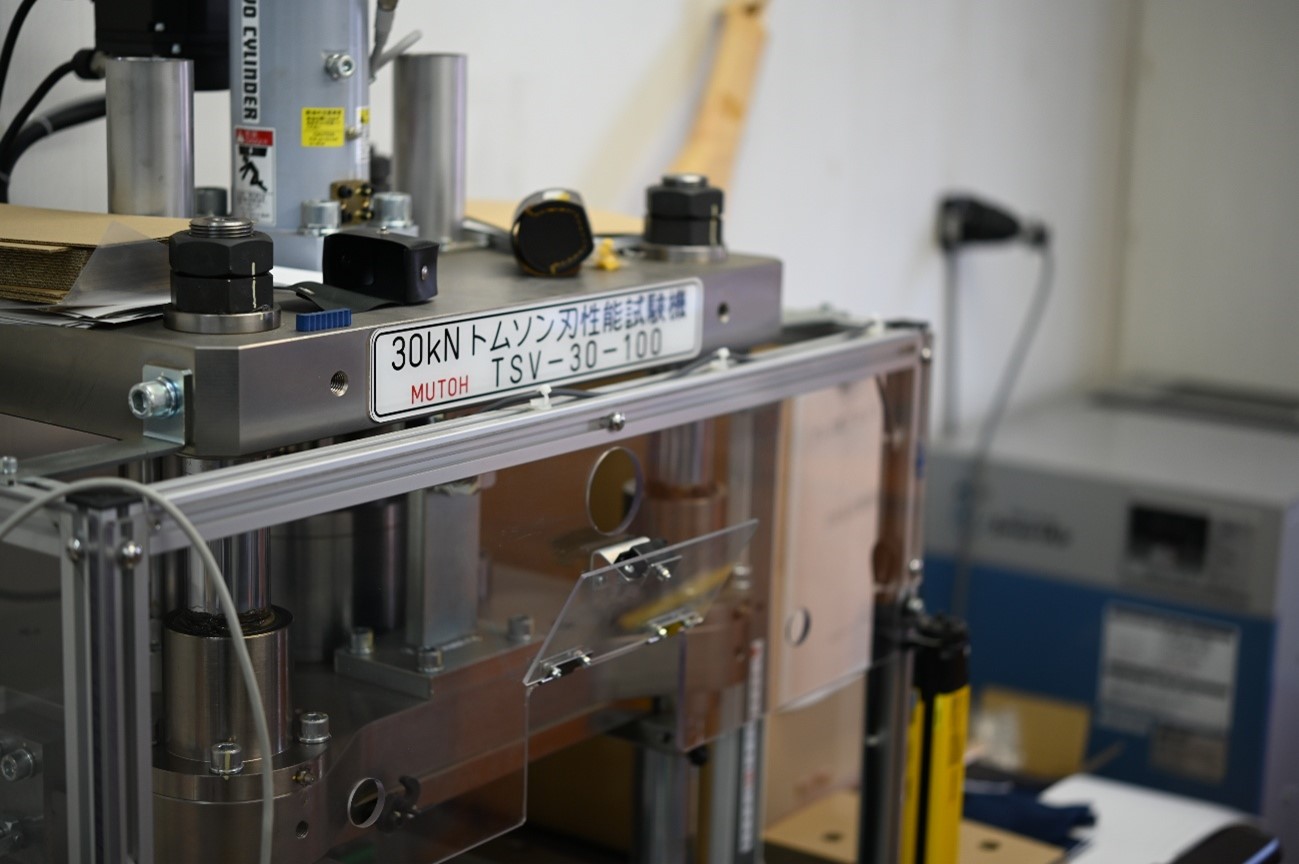

The introduction of die cutting was considered.

However, steel rule accuracy and actual die cutting performance were still unknown.

To address this, we used a testing machine to thoroughly evaluate the compatibility between the steel rule and the material—examining pressure, edge penetration depth, cross section quality, and other critical factors from every angle.

By conducting repeated tests under multiple conditions, we identified the optimal die cutting parameters.

Result

The verification confirmed that there were no issues with either the steel rule or the material, enabling cuts that preserved both beauty and precision.

With the introduction of die cutting, the minute irregularities that had occurred during manual operation were eliminated.

As a result, productivity improved significantly, and the entire process advanced to a new level.