CASES

MISSON

Resolving remaining cut-off problems

Drilled punches made by another company were used for cutting out Velcro tape.

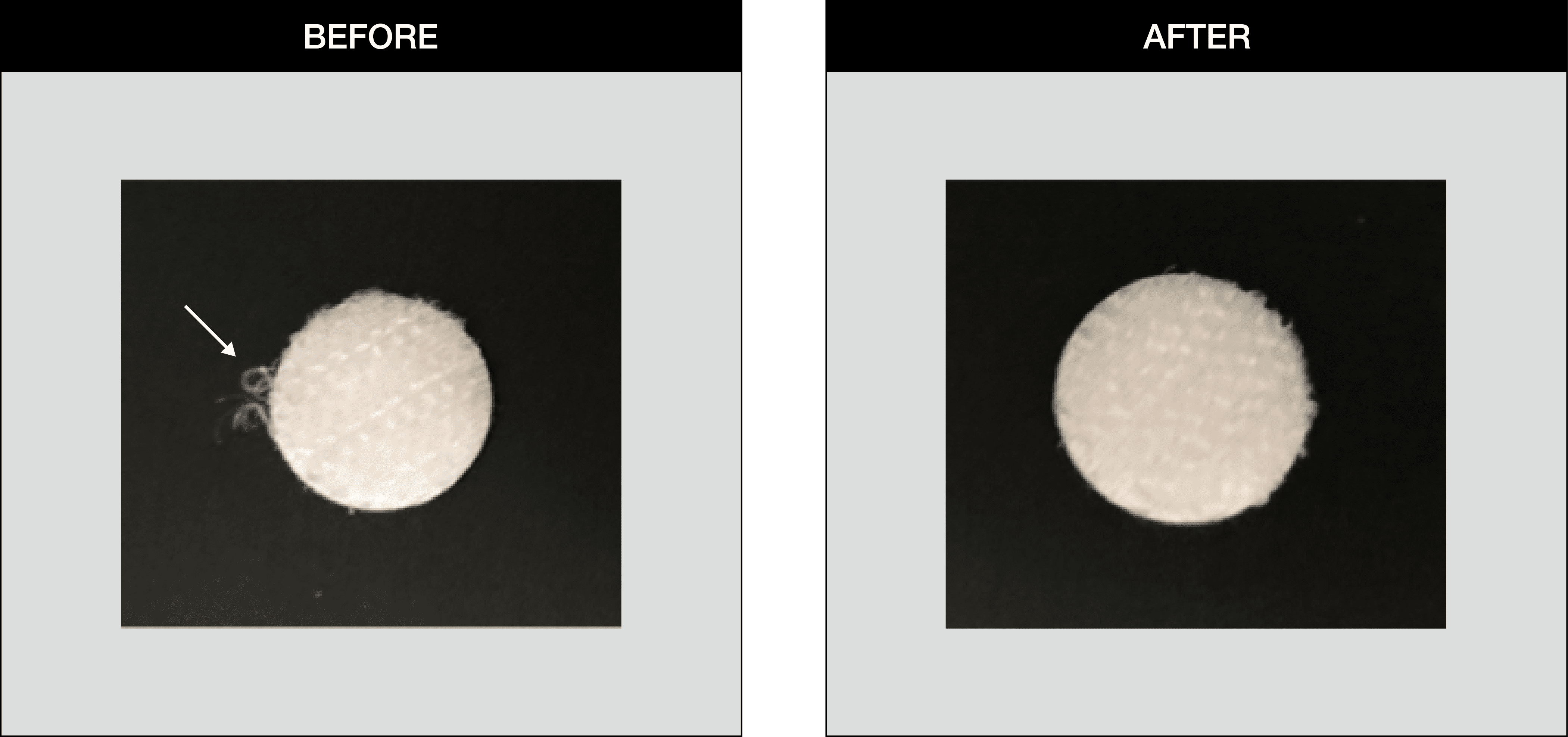

The customer consulted with us about a problem with fiber remaining on the surface (fluffing).

They tried to improve the problem by using a different shaped punches made by another company, but the result was the same.

Material: Velcro Tape, thickness about 1.0 mm (thickness after compression)

Product used: Another company's drilled punche 15φ 0.7x23.6H

SOLUTION

Drilled Punch (W) enabled clean cutting without leaving a residue of sharpness

We proposed the use of Drilled Punches with a mirror finish on the cutting edge and changing the hardness of the ejection rubber.

<Details of the proposal>

Punch : Nakayama-made Drilled Punch (W) 15.0φ 0.7x23.6H

Ejection Rubber : Green Rubber (H) KSA-170 7.0mm

Results of use

Our punch was able to cut cleanly without leaving a residue.

The mirror finish of the cutting edge made the height of the punch aligned, and the resistance at the time of cutting was reduced.

And it led to good results in terms of height uniformity and lower resistance during cutting.

The change in the hardness of the ejection rubber has also resulted in a more stable cut, and it also hold the sheet firmly, which may have resulted in a more stable cutting.