CASES

MISSON

Improved blade bendability

The customer wants to use a cutting rule of higher hardness than the current one to improve the durability of the cutting rule (dieboard).

However, it is difficult to change the hardness in consideration of the blade bendability because the edge or the body of the blade is cracked.

SOLUTION

We proposed "ST series" with special heat treatment.

ST series features a special heat treatment that improves blade bending workability while maintaining hardness.

The improved blade bendability allows the use of blades of higher hardness than those used in the past.

Results of use

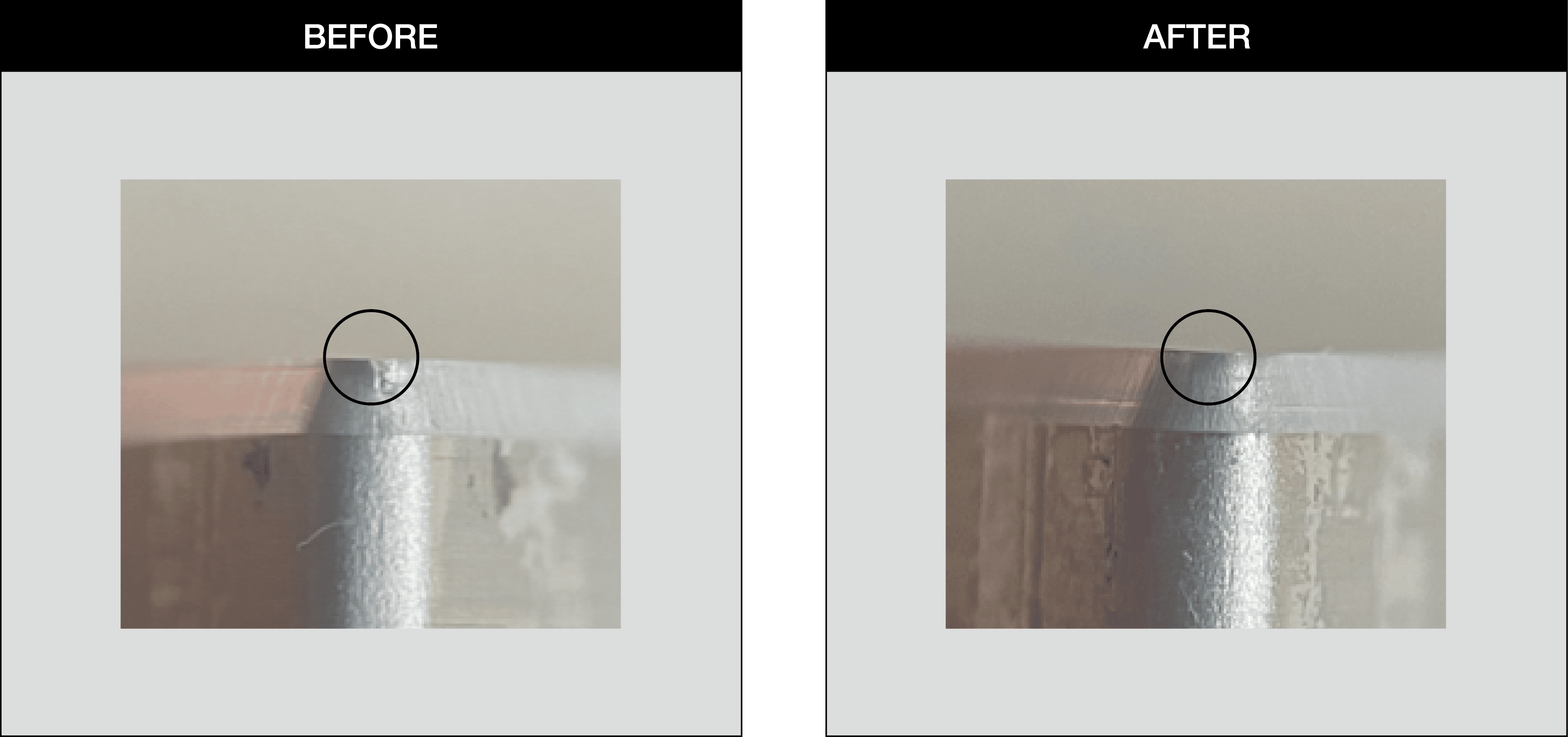

The customer could change the hardness from Body : HS45 / Edge : HS75 (4575) to Body : HS50 / Edge : HS80 (5080).

There were no cracks in either the body or the edge of the cutting rules, and the cutting process could be performed as usual. Moreover, the durability of the dieboard was improved, and it was confirmed that the durability was about 1.5 to 2 times longer than that of the conventional dieboard.

In addition, by enabling the selection of a blade with higher hardness, work that used to use a blade thickness of 0.9t or 1.0t can now be handled with a blade thickness of 0.7t, thereby improving workability during dieboard fabrication.