CASES

MISSON

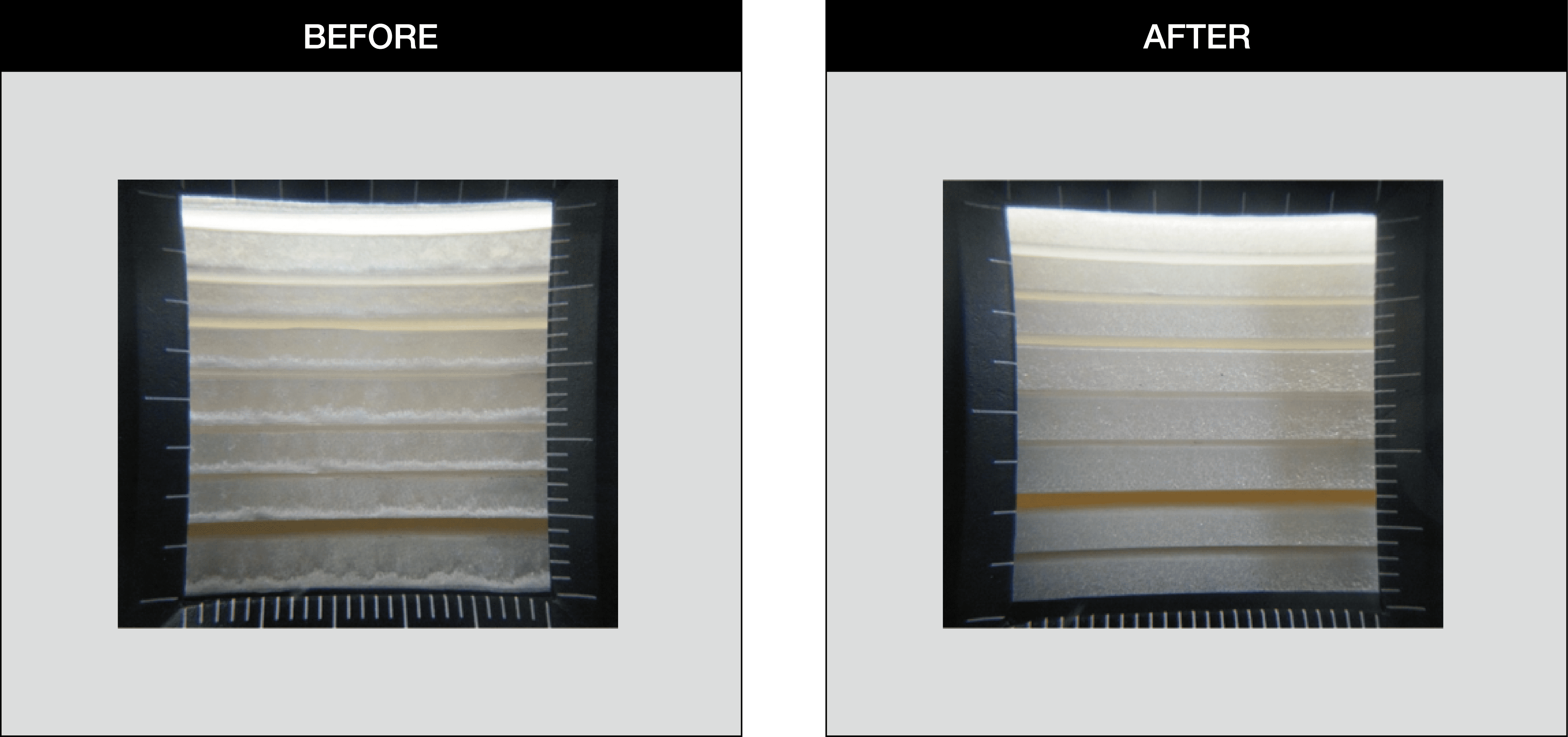

Burr of PSP cut surface

When cutting food trays (PSP), burrs appear on the cut surface.

Cutting itself is not a problem, but the customer wants to finish the cut surface smoothly.

Blade used : NCD1030 1.0×30.0 5072, Angle 43° (Double Long Bevel)

Object to be processed: PSP 3.0mmt (food tray)

SOLUTION

The one and only sharpness, "Nakayama Hi-MIR series"

We proposed Hi-MIR in expectation of less cutting pressure during the cutting process.

Proposed blade : Hi-MIR1030 1.0 x 30.0 5580 Angle 43° (Double Long Bevel)

There was no change in the layout of the dieboard and only the blade was changed, but the cut surface was satisfactory with no burrs.

Hi-MIR has a mirror finish (MIR), which lowers cutting pressure during the cutting process.

As a result, the sheet could be cut without being squashed.