BEAUTIFUL CUTLINE.1世紀という歴史の結晶。

液晶テレビに利用されるフィルムから高付加価値パッケージまで、世界中のあらゆる材質を打ち抜くトムソン刃の頂点「ナカヤマMIR」。 創業から約1世紀、トムソン刃に向き合い、熟知し、独自の加工技術とノウハウを持つナカヤマだからこそ、この「MIR」は誕生し、今もなお進化を続けています。 極限まで抑えた高さムラ、鏡面仕上げから生まれる刃先部の究極の鋭さ。 これらによるシャープで美しい切断面は、ナカヤマの歴史の結晶と言えるでしょう。

Nakayama MIR are ultimate CUTTING RULES, used to cut through all sorts of materials around the world, from films used in LCD TVs to high-added-value packaging.Over the course of approximately a century since our founding, Nakayama has engaged with CUTTING RULES, gotten to know them thoroughly, and has developed unique processing technology and know-how. It is in this context that MIR was created and continues to evolve.With unevenness of height kept to the utmost minimum and a mirror finish applied, the blade edge boasts the ultimate sharpness. These features achieve a keen and beautiful cutting surface that can be said to embody Nakayama’s history.

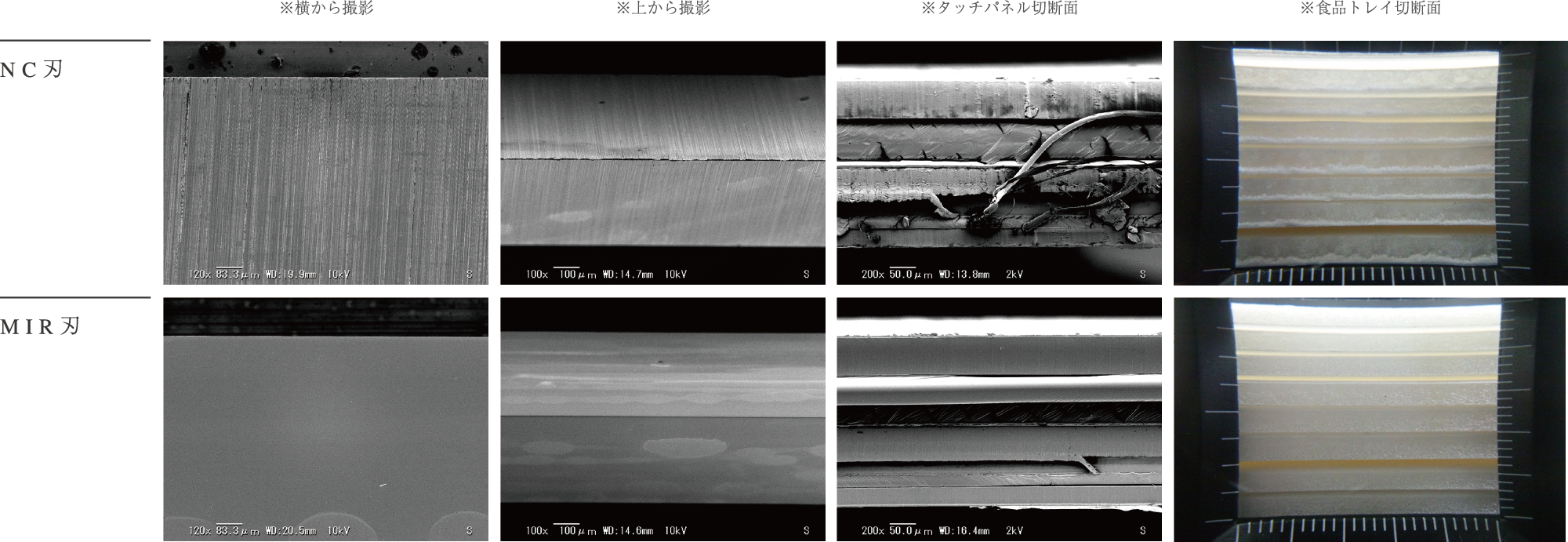

ナカヤマMIRの最大の特徴は「唯一無二なる切れ味」と「高さ精度」だが、同様に「折り曲げ性」も高い点が挙げられる。

画像からも分かるようにナカヤマMIRは、従来品に比べてより滑らかな研磨面を実現。

極限まで抑えた高さムラ、鏡面仕上げから生まれる刃先部の鋭さはもちろん、加工のしやすいナカヤマMIRは様々な問題を解決する刃と評価を得ております。

The key characteristics of Nakayama MIR are unparalleled sharpness and height precision, but it also features a high degree of bendability.

As the image shows, Nakayama MIR achieves a smoother polished surface than conventional products.

In addition to blade edge sharpness resulting from utmost minimization of height unevenness and a mirror finish, Nakayama MIR is easily processed and gains a reputation for being able to solve a wide range of problems.

より良い製品づくりの為にナカヤマではMIR刃を生み出す機械設備そのものも、自社で設計し製作しています。その為日進月歩常にアップデートし、より良い製品を実現できます。また砥石も長い歴史の中で試行錯誤を重ねMIR刃に最適な物を選んでいます。

また、MIR加工の前後工程も大切であります。前工程の熱処理、前研磨等、ベースづくりに注力し、MIRが完成した後工程にも力を入れ、製品サイズに切断する切断機も非接触の自動化の改良に成功しました。

To make better products, Nakayama designs and manufactures the equipment used to produce MIR blades in-house. This means we can steadily update and constantly improve our products.Also, we have selected the optimal grinding wheel for MIR blades based on trial and error over the course of our long history.

The MIR pre- and post-process stages are important as well. We focus on fundamentals such as heat treatment and pre-polishing during the pre-process stage, as well as during the post-process stage after MIR is complete, and succeeded in improving non-contact automation of cutting equipment that cuts to exact product sizes.

遡ること約30年。1992年に顧客から「曲げても刃先が割れないトムソン刃が欲しい」というリクエストに応える為に研究開発を開始。開発は容易ではなく、何度も試行錯誤を繰り返しました。刃先の割れが砥石目より発生する。そこでその溝を無くそうとして細かい砥石で何度も削る。溝を細く浅く。そうする過程でようやく刃が光り、溝が無くなることで折り曲げにも強く、切れ味も良い刃が生まれました。 製品名は鏡(mirror)にかけてMIRと名付けました。また、刃物を磨くという方法だけではなく、砥石にも着目し、MIRの為だけの砥石を作り、現在の品質と製品安定性が在ります。

About 30 years ago, in 1992, we launched research and development to fulfill customer requests for “CUTTING RULES with blade edges that do not break even when bent.”Development was not easy, and a cycle of trial and error was repeated many times. The grinding wheel grain produced cracks in the blade edge. For this reason, we ground it many times with a fine grinding wheel to minimize the groove and make it as thin and shallow as possible.After this process, the blade finally emerged shining and the groove disappeared, resulting in a blade that can accommodate bending and boasts excellent sharpness. The product name “MIR” is derived from “mirror.”In addition to the blade polishing method, we also focus closely on the grinding wheel and produce grinding wheels only for MIR, which has led to the current high level of product quality and consistency.